E Coating Vs Powder Coating

1

E Coat Basic Powder Coating Machine Electron Pdf Catalogs Technical Documentation Brochure

Powder Coating Minnesota Industrial Coatings

E Coating Vs Powder Coating Sharretts Plating Company

What Is A Functional Coating Decc

10 Horizontal E Track Rail Black Painted Tie Down

Paint additionally has solvent.

E coating vs powder coating. Powder coating is popular right now and therefore we get requests for powder coating almost every day. Whereas zinc plating works through cathodic protection, powder coating utilizes barrier layer protection. With electrophoretic deposition, the substrate of a metal is immersed in a liquid solution that may comprise an epoxy, paint, or some of the other water-based solutions.

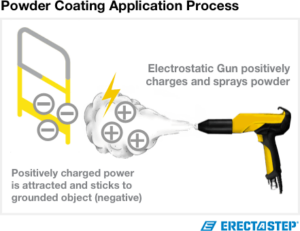

One such option is electrocoating, also known as e-coating, electric painting, electrophoretic coating and electroplating. If you’ve ever tried cleaning powder coat, you know how difficult it is. A spray gun is used to electrostatically apply the particles onto the surface of the substrate.

We have a locker room that has metal lockers needing to be re-painted. But powder coating is generally far thicker than e-coating, involving the deposition of significantly more material, so it is probably reasonable to say that powder coating is more expensive. Powder coating only needs one coat of powder to be applied effectively.

E-coating is able to deliver this within the range of 12 – 13 microns. Powder Coating Cost vs Paint Cost. Like plating, coating is applied to metal surfaces for protective purposes.

It’s highly used to apply finishes to vehicles. Ceramic coating is a high-solid paint product which is concentrated with ceramic powder. Both have to be baked for crosslinking.

This bonds with the negatively charged surface of the base component, creating a rich protective layer. Electrostatic coating is a manufacturing process that employs charged particles to more efficiently paint a workpiece. Also known as e-coating or electro-coating, this metal finishing technique is more akin to electroplating than it is to powder coating process.

However, e-coating is considered a “wet” process while powder coating is considered a “dry” process. Does powder coating need a primer?. With the second one, the product must be submerged into a mix between a water-based solution and the pigments to paint.

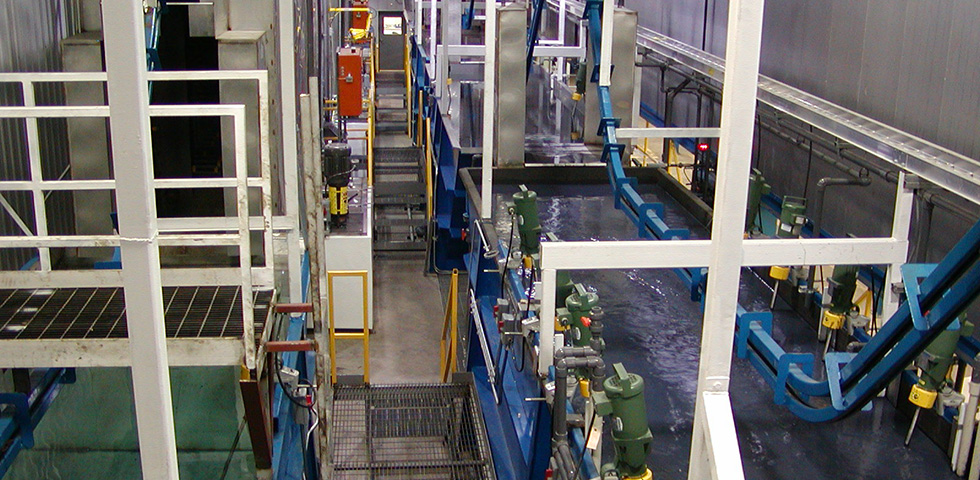

Electropainting is usually achieved through submerging the components into the electro paint bath and applying an electrical charge through the bath. The powder applied consists of a mixture of minute particles of resident pigment that are sprayed electrostatically onto a surface. If the item is to be used in a lighter service e-coating may be preferred because it does not corrode and can last longer.

They are not as slippery as enamel painted kettlebells and are not as rough as powder coated kettlebells. The minimum thickness requirement is 12 microns. The coating industry has a variety of methods to coat metals with the perfect finish.

Both are available in epoxies and PUs. The immersion process with e-coat will cover those IDs in the tubes and channels (provided, of course, there is no air pocket to restrict coverage). Epoxies in powder form are applied thicker than e-coating and therefore can be better for some applications.

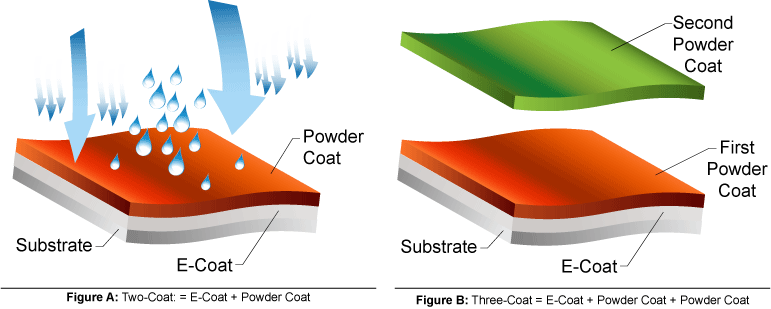

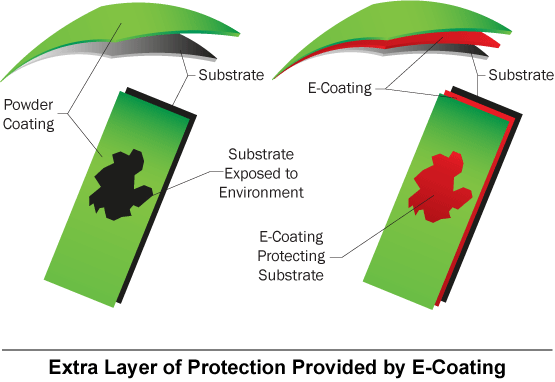

Powder coating is an organic process that involves barrier-layer protection. Powder coating is a finishing process in which a coating is applied electrostatically to a surface as a free-floating, dry powder before heat is used to finalize the coating. E-Coating as a Powder Coat Primer For Exceptional Corrosion Resistance.

The fact that the powder particles are charged is what allows them to adhere. Powder coats are strong, attractive, long-lasting and applicable to various surfaces. They are not as slippery as enamel painted kettlebells and are not as rough as powder coated kettlebells.

Paint is more widely available. Compared to Powder Coating, E-Coating is a thinner coating which does not significantly inhibit thermal properties. I would like to get your opinion on something.

The average cost of powder coating is about $2,000 vs the average cost of painting which is about $1,900. E-coating is known to be a “wet” paint process, due to its pure water based solution. This process is very dry, as there isn’t any liquid involved.

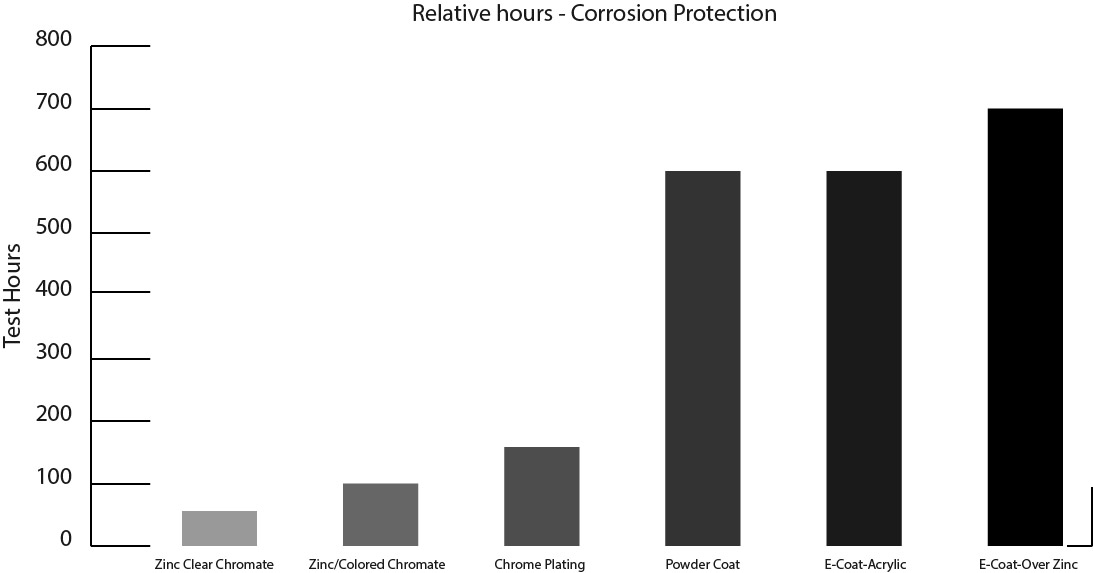

E-coating vs Powder Coating Due to both industrial finishes offering extreme protective-Coatings and corrosion resistance, the e-coating vs powder coating debate can be ongoing. Powder Coating is a simple coating technique which is applied directly (powder) to the object. We also carry a wheel that has E-coating with a silver powder paint finish, like part # AM746, that you referenced.

Here are the differences between the two main types of coatings:. Powder coatings need a much hotter oven to melt the particles so that they can flow and react chemically to form a smooth finish on the workpiece. It is particularly popular for applying a finish to vehicles.

The first one is a mix between painting pigments and epoxy resins. A spray gun is used to electrostatically apply the particles onto the surface of the substrate. The numerous benefits of powder coating are best outlined as follows:.

The terms e-coating and e-coat also refer to this process. At Great Dane Powder Coating, Inc., our experts work with you to determine the best approach to your powder coating needs.While not all products need disassembly, stripping, cleaning, and sandblasting in preparation, our full-service shop is ready to handle every need. BUY Dual Voltage Powder Coating System HERE:.

Powder coating is an alternative to painting that has grown in popularity in recent years. Paint, in the form of either powdered particles or atomized liquid, is initially projected towards a conductive workpiece using normal spraying methods, and is then accelerated toward the work piece by a powerful electrostatic charge. Powder coating is mostly used for coating of home appliances, Aluminum extrusions, drum hardware along with automobile and bicycle spares.

Unfortunately, too little is known and the process is under-utilized in today’s industry. Anodized and powder coating. Also, does powder coating last over a long period of time?.

Paint debate, powder coat durability is superior. For low-to-moderate production volumes, outsourcing can be a cost-effective way to obtain the advantages of professional e-coat application for a given part or product. In other words, powder coating involves the formation of an impenetrable outer layer, which prevents water and other oxidizing materials from accessing.

We offer wheels that have a galvanized finish, like part # AM747, with a 6 X 5.5 bolt pattern. It has some dissimilarity with the conventional liquid paint method since powder coating is done electro statically. Powder coating cannot deliver much less than 30 microns and will normally work within a 30 – 60 micron range.

The powder coating process contrasts the e-coating process in that a dry powder is electrostatically charged and then deposited on the material. E-coat is much easier despite being able to hold chalk just as well. Powder coating is mostly used when you need a durable protective finish added to a metal product.

This means that our e-coated kettlebells are more durable than any kettlebell that is powder coated. The process of powder coating is the application of a dry powder to a part. Powder coating is a great alternative to painting.

An e-coat system with the appropriate supporting equipment, such as the treatment system for process fluids represents a significant capital and staffing investment. The smaller parts can be done quickly, and can be cured in the oven in high quantities. Polyester, polyurethane, polyester-epoxy, straight epoxy, and acrylics.

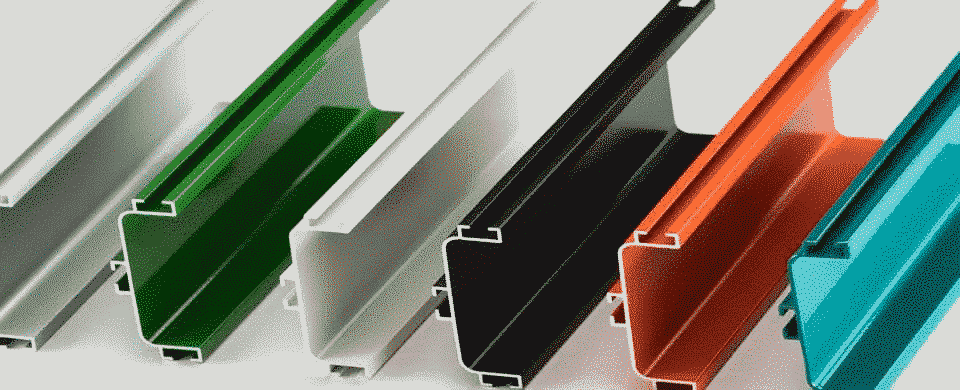

When it comes to the type of aesthetic or desired appearance, the type coating matters heavily. E-coating involves a lengthy pre-treatment process with multiple washing, cleaning, rinsing and conditioning stations. Powder coating is a type of spray painting while e-coating is a cross between plating and painting.

Which method would be best - epoxy paint or powder coating?. In powder coating the powder particles are charged. The powder coat processes are still line-of-sight with some electrostatic wrap.

It is less expensive, and it is easier to creating match colors for existing paints. While powder coating has proven superior when compared to traditional liquid paint, other coating methods offer similar advantages as powder and therefore can be harder to differentiate. In E-coat the liquid is charged and an electrochemical reaction deposits a film.

The process is used to apply a durable, protective finish to almost any type of metal product. The advantages of powder coating When it comes to aesthetics, durability, and sustainability of coating, powder coating delivers a harder finish. Factors that influence cost include coating thickness, types of materials used, the application of pretreatment processes and the current price of zinc.

Powder Coating is not only easy but it is also extremely durable and chip resistant. Also epoxies applied as a powder coating have higher crosslink properties than e-coat, making them stronger and more chemical resistant. But unlike electroplated surfaces, powder coated surfaces are essentially covered in paint – not metal.

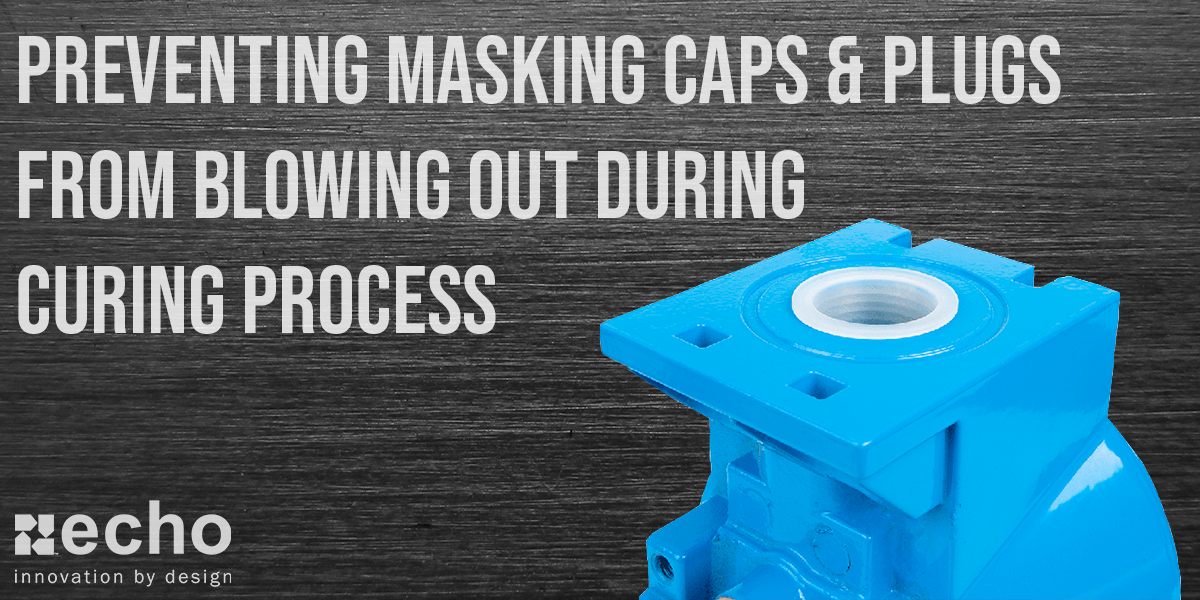

Threads and holes do not require masking due to the thin coat. We are not fans of powder coating due to the following reasons:. The list goes on, and we could get into better scratch resistance, toughness, and hardness than traditional liquid paints, but let’s take a look at some of the different powders used that help achieve these characteristics.

While powder coating electrifies powdered paint particles, the e-coating process involves immersing the surface in a pool of liquid paint that is then electrified. High-gloss finishes are easier to achieve. Initially developed for the aerospace industry, the process is now used throughout the auto industry on components that include exhaust manifolds, headers, mufflers, and intake manifolds.

Powder Coating vs Paint. And powder coatings can provide incredible corrosion and chip resistance. In general, the initial cost of hot-dip galvanization is higher than powder coating.

For a proper curing, the substrate must be at this temperature for at least 10 minutes. Good quality spray paints need to apply 12 – 18 microns to be certain of maintaining a 12 micron minimum. The only difference is how the color is applied to the stamped metal part.

The best way to choose between them both is by determining exactly what you need from the paint. Powder coating is extremely difficult to remove for refinishing, even with sandblasting. Coating differs from electroplating in that it’s performed by electrostatically applying a free-flowing powder to a surface, then curing it under heat.

Powder coating is a type of spray painting while e-coating is a cross between plating and painting. It cracks, chips, flakes and peels off, leaving the metal exposed to moisture and rust. In the powder coat vs.

The type of electrode. Powder Coating › Powder Coating. Powder coating creates a thick, adhesive finish that lasts longer than the typical coat of spray paint.

Most powder coatings reach this stage in an oven heated to 350 to 400 degrees F. The powder can be made of any number of products:. E-coating is also better at reaching difficult areas because it is immersed in paint, allowing a more thorough distribution of the coat compared to powder coating.

Powder coating also offers a wide range of specialty effects that are hard to achieve through traditional methods. As an advanced method of applying a protective and decorative finish to a metal surface, powder coating is beneficial for individual consumers and heavy industry. Powder coating is best intended for smaller parts.

Powder coating is a dry process, while E-coating is a wet process:. The majority of commonly used powders consist of a precise combination of epoxy or polyester resins, pigment and curing agents. Does moisture have any affect on something that is powder coated?.

Compare Powder Coat vs Paint Costs Powder Coat Overview. This means that our e-coated kettlebells are more durable than any kettlebell that is powder coated. Galvanizing tends to result in lower long-term maintenance costs, although.

Powder coating takes a much different approach to protect a substrate against corrosion. A-coating bonds to metal using a chemical reaction, while E-coating bonds through the application of an electrical current. The greatest distinction between these two technologies is mode of application.

The material is then cured, just as with e-coating, which causes the particles to melt and results in the desired finish. While e-coating is considered to be a “wet” process, powder coating involves the application of a dry powder consisting of a precise combination of epoxy resins and various curing agents. (It also almost goes without saying that powder coating is much safer, as well, since the combination of liquid and electric current in e.

E-coating is a process that has been used since the 1970s for the corrosion protection of metal parts and the production of smooth, durable and protective finishes. However, there is an important difference between both of them:. Like e-coating, powder coating produces a very resilient finish.

While e-coating is considered to be a “wet” process, powder coating involves the application of a dry powder consisting of a precise combination of epoxy resins and various curing agents. Typical thickness is 0.5 to 1.5 mils but could even go up to 5 mils if required;. E-Coat is also able to be applied thinner than powder coat which allows the imperfections in the cast iron to provide the grip and make it easier to clean.

In fact, epoxy-based powder over good pretreated metal can withstand up to 3,000 or more hrs salt spray resistance. Powder coatings can be applied as a rather thick film, easily depositing 3.0 to 6.0 mils in one pass. An electrostatically charged coating is applied to the surface – specifically a positive charge to the dry powder (thermoplastic or thermoset polymer).

Perhaps a shop that offers both will confirm or refute this for me.

Powder Coating Vs E Coat Is E Coating The New Powder Coating

The Architect S Guide To Powder Coatings

Powder Coating Machine With Electrostatic Gun E Coat Basic Electron

China Powder Coated Or E Coating Customized Compass On Wooden Shelf Bracket China Furniture Hardware Carbon Steel

Dare To Compare Powder Coatings Vs Liquid Paint For Automotive Applications Tiger Coatings A Better Finish A Better Print For A Better World

Powder Coat Masking Hi Tech Flexible Products

Two Coat Powder Process Fights Corrosion

E Coat Master H With 50 Lt Ss Hopper Electron Powder Coating Facebook

Electrocoating Company High Volume Industrial Electrocoating

Powder Coating Vs Traditional Lube Taco S Pros And Cons List The Reloaders Network

E Coating Vs Powder Coating What S The Difference Membracon

H E Orr Company Combines E Coating And Powder Coating On One Production Line For Superior Protection And Significant Cost Savings He Orr

Powder Coating Vs Wet Paint And Plating

Adding E Coat To An Existing Powder Coating Line Products Finishing

Pym Wildsmith We Get Asked About Whether E Coat Or Powdercoating Is The Right Process For The Job And The Answer Is Usually That It Depends On Your Needs We

Services Hartford Finishing Inc

St Louis Wheelblasting Services Microfinish

E Coating Excellent Coverage And Application Properties

New Finish Inc Powder Coating Liquid Coating E Coating Sandblasting

Powder Coating Vs Paint See The Durability Of Powder Coating Eastwood Youtube

Kb Buying Powder Coat Yes4all Vs E Coating Diamond Pro Kettlebell

Electron Manual And Automatic Powder Coating System E Coat Master

China Powder Coated Or E Coating Customized Compass On Wooden Shelf Bracket China Furniture Hardware Carbon Steel

E Coating Minnesota Industrial Coatings

Powder Coating Vs Paint Saferack

Proto Tech Tip Powdercoat Textures Gloss Vs Matte Vs Sandtex Youtube

Silicone Tapered Plugs For Powder Coating

E Coating Vs Powder Coating What S The Difference Membracon

To A Pdf Version

Used Powder Coating Equipment For Sale Powdercoatingonline Com

kg Tweener Military Grade E Coated Or Powder Coated Cast Iron Kettl Great Lakes Strength Manufacturing

Coatings And Fabrication

Industrial Systems By American Industrial Sales Llc Featuring Powder Coating Equipment Industrial Overs Washers And E Coat Systems

Electrophoresis Powder Coating Line Buy Chassis Tec Talis Pretreatment E Coat Paint Line Electrophoretic Paint On China Suppliers Mobile

E Coating Process

Industrial Powder Coating Systems Mechanical Finishing Systems Durusa 574 312 0923

Central Wisconsin Finishing Powder Coating

What Does Ed Coating Mean For Bicycles Handsome Cycles

What Is A Functional Coating Decc

Everything You Need To Know About Powder Coating Vs Electrocoating E Coating Cadillac Coatings Powder Paint Edmonton Alberta

E Coating Valmont Coatings

E Coating

E Coating Job Great Dane Powder Coating

E Coat Converyorized Painting System Upper Sandusky Ohio

Military Coatings Shurpac Inc Metal Finishing

Powder Coating Vs Paint Saferack

Troubleshooting Electrocoating Avoid E Coating Defects

Powder Coating Vs E Coating

Rogue Kettlebells In Depth Review New E Coat And Old Powder Coat Included Garage Gym Reviews

E Coating Vs Powder Coating What S The Difference Membracon

Powder Coating Minnesota Industrial Coatings

China Ed Coating Line E Coat Paint Line Electrophoretic Paint Equipment China Electrophoretic Coating Line E Coat Powder Coating Line

Amazon Com Wosume Outdoor Bistro Set E Coated Powder Coated Steel Dark Gray 3 Pcs Home Kitchen

D Zolve 1012 Room Temperature Powder Coat Dissolver Solvent Kleene

Rogue Kettlebells In Depth Review New E Coat And Old Powder Coat Included Garage Gym Reviews

Is A Third Coat Necessary With A Two Coat Top Coat

Powder Coated Bollards Ours Do Not Need To Be Painted Sino Conceptsinoconcept

Powder Coating Supplies Decoral America United States

E Coat And Powder Coating Plant Surface Treatment Cti Systems

84kg Tweener Military Grade E Coated Or Powder Coated Cast Iron Kettl Great Lakes Strength Manufacturing

1

China Auto High Speed Liquid Powder E Coating Production Line With Conveyor System For Sale China E Coating Equipment Powder Coating Machine

E Coat Versus Powder 18 06 15 Pci Magazine

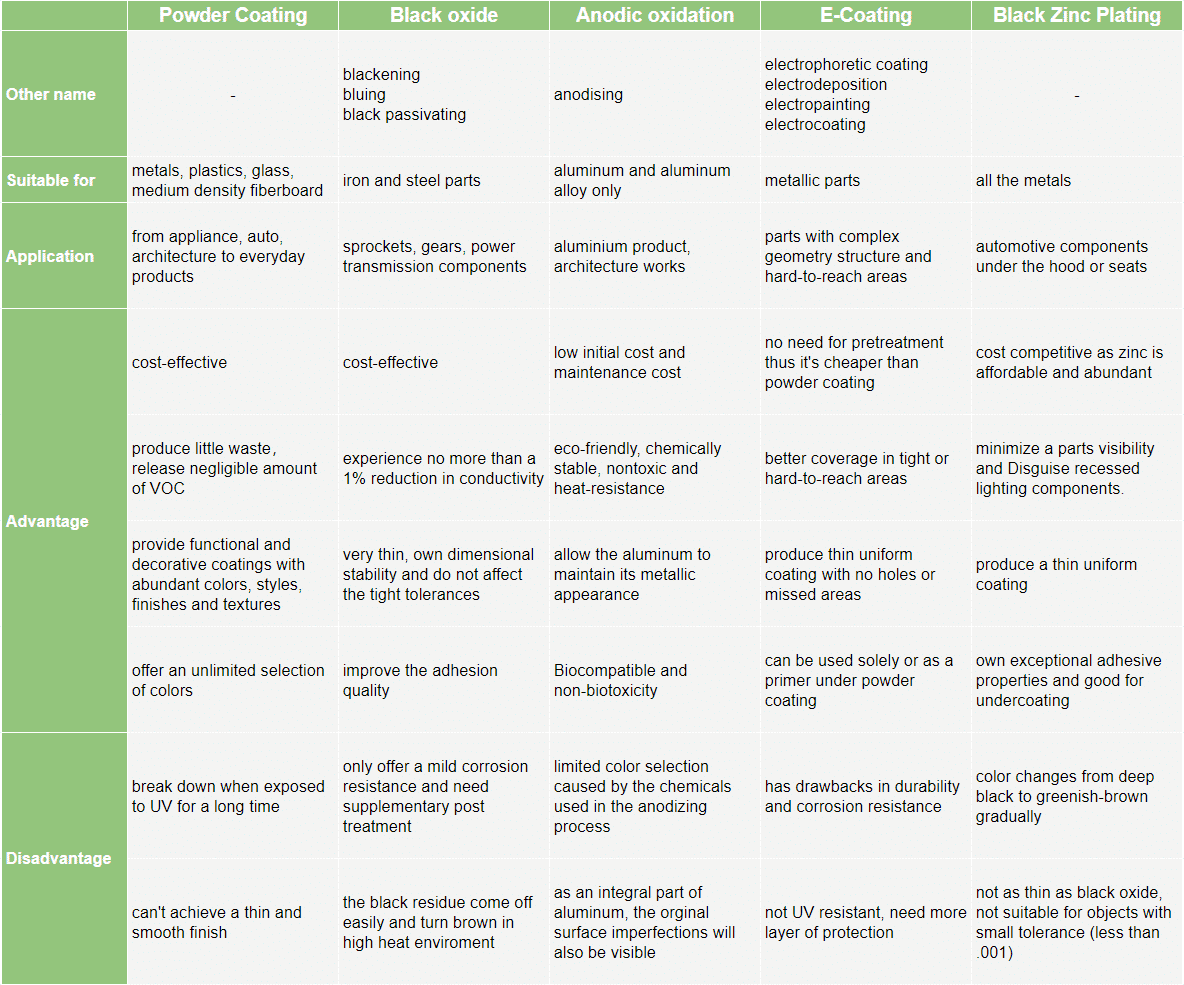

Black Coating Comparison E Coating Vs Powder Coating Vs Black Oxide Vs Anodic Oxidation Vs Black Zinc Plating Facfox

Powder Coating Room Great Dane Powder Coating

E Coat Masking Hi Tech Flexible Products

Powder Coating Services Inc Full Service Metal Finisher

Rogue Kettlebells In Depth Review New E Coat And Old Powder Coat Included Garage Gym Reviews

E Coat Master H With 50 Lt Ss Hopper Electron Powder Coating Facebook

Central Wisconsin Finishing

Paint Removal Paint Stripping Services Company

A L Hansen Mfg Co

Electrocoating Company High Volume Industrial Electrocoating

Powder Coating Vs E Coat Is E Coating The New Powder Coating

Effect Of Silane And Zirconia On The Thermal Property Of Cathodic Electrophoretic Coating On Az31 Magnesium Alloy Sciencedirect

New And Used Powder Coating Equipment Wagner Used E Coat Line For Sale E Coating Equipment Used E Coat Systems Powder Coating Ovens Syntecfinishing Com

High Tech Steel Wheel E Coating Line Anfengtai Coating Co Ltd

Rogue Kettlebells In Depth Review New E Coat And Old Powder Coat Included Garage Gym Reviews

Powder Coating Line E Coating Line Electrophoresis Youtube

Two Popular Industrial Coatings Powder Coating V S Galvanizing

Brand New E Coat Series Powder Coating Equipment Istanbul Istanbul Turkey Electron

Q Tbn 3aand9gcsyt7xs9tulgr2ynqzzrxnoxj0oibprnm Nhqwwlui Usqp Cau

Black Coating Comparison E Coating Vs Powder Coating Vs Black Oxide Vs Anodic Oxidation Vs Black Zinc Plating Facfox

Powder Coating Minnesota Industrial Coatings

E Coating Minnesota Industrial Coatings

Powder Coating Supplies Decoral America United States

E Coating Excellent Coverage And Application Properties

Q Tbn 3aand9gcqnnm X02vkh84zcm18uhu8 Wurfkxi6fr0teytbic Usqp Cau

Powder Coating Minnesota Industrial Coatings

Electrophorysis E Coating Better Than Powder Coating For Outdoor Wrought Iron Patio Furniture

E Coating Vs Powder Coating What S The Difference Tomburn Ltd

E Coating Electrocoating Powder Coating Services Inc

Android Flint Aquence Coating Powder Coating And Assembly Ppt Download

Duplex Coating

Automatic E Coating Line Anfengtai Coating Co Ltd

E Coating

E Coating Vs Powder Coating Pym Wildsmith E Coat Process

New And Used E Coat Systems Powder Coating Equipment Autodeposition Finishing Systems